In modern manufacturing, enhancing the durability, strength, and wear resistance of metal components is essential for maintaining performance and reliability.

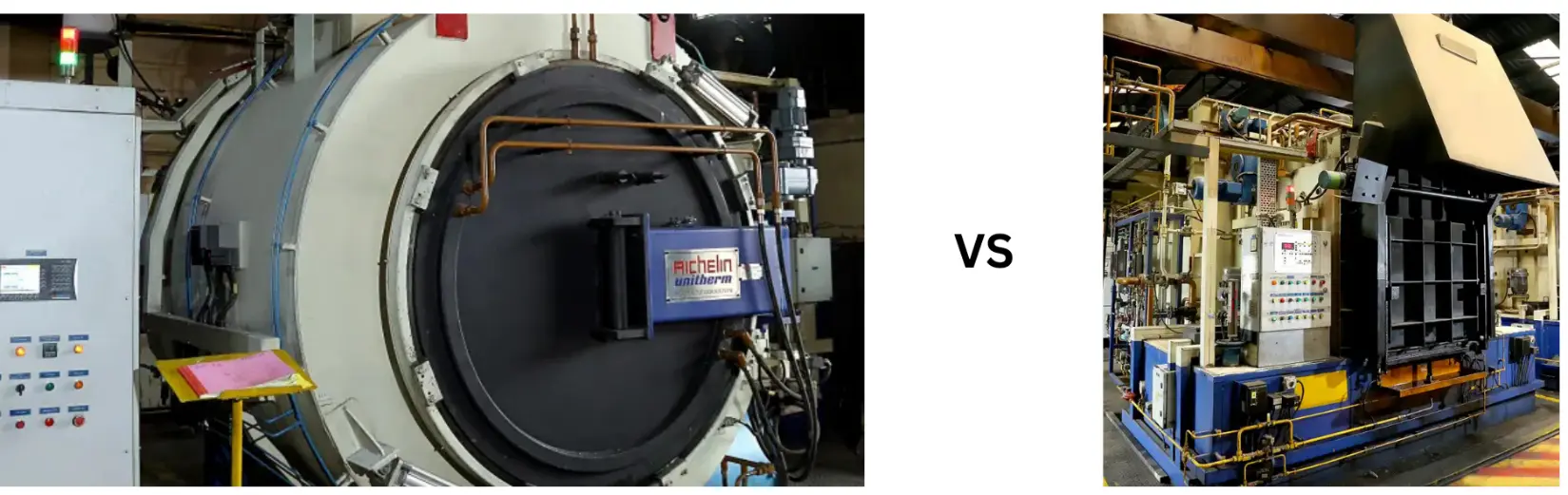

Surface hardening methods play a crucial role in achieving these goals, and among the most widely used techniques are the

carbonitriding and

nitrocarburizing processes. While both belong to the heat treatment process category, they differ significantly in temperature, results, applications, and performance outcomes. Understanding these differences helps industries choose the most suitable method when opting for

heat treating services or searching for nitriding process near me for specialized components.